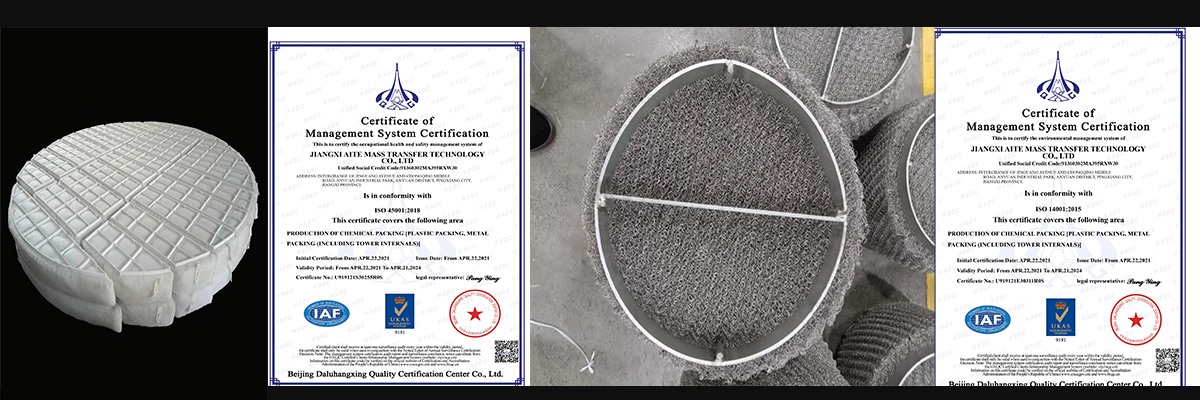

The wire mesh demister

The wire mesh demister is composed of two parts: the steam liquid filter mesh pad (assembled by several mesh blocks) and the support. The mesh block is composed of several layers of Pingpu corrugated vapor-liquid filter screen, grid and distance rod.The wire mesh demister is a gas-liquid separation device. When the gas passes through the wire mesh pad of the demister, it can remove the entrained mist and other moisture substances. HG/T21618-1998 standard is a new standard revised on the basis of the original Ministry of Chemical Industry HG5-1404-81, HG5-1405-81 and HG5-1406-81, combined with the actual use experience of wire mesh demister and the advanced technology in the imported device.

The materials selected for the screen demister are divided into two types, one is plastic and the other is metal. The plastics are subdivided into PP polypropylene, PE polyethylene, PVC polyvinyl and PTFE polytetrafluoroethylene. Metal is subdivided into 201, 304, 304L, 321, 316, 316L, 310S, NCU-30, Monel400, N201, and other materials. The wire mesh demister

Wire mesh demister, which is mainly used for separating diameters greater than 3 μ m~5 μ When the gas with mist rises at a certain speed and passes through the wire mesh on the grid, the inertia of the rising mist makes the mist collide with the filament and adhere to the surface of the filament. The fog on the surface of the filament is further diffused and the gravity sedimentation of the fog itself makes the fog form large liquid droplets and flow along the filament to its interlacing place. Due to the wettability of the filaments, the surface tension of the liquid and the capillary action of the filaments, the droplets become larger and larger, until their gravity exceeds the combined force of the rising buoyancy of the gas and the surface tension of the liquid, they will be separated and fall, and flow to the downstream equipment of the container. As long as the operating gas speed and other conditions are properly selected, the demister efficiency can reach more than 97% after the gas passes through the wire mesh demister, which can completely remove the fog.